“From Film to Fabric—Flawless Every Time.”

DTF, or Direct to Film printing, is a cutting-edge technique that lets us transfer high-resolution, full-color designs onto a wide range of fabrics. Using special PET film, eco-friendly inks, and a heat press, DTF delivers sharp, durable prints that are perfect for everything from cotton T-shirts to performance wear.

This method allows for detailed artwork with vibrant colors and smooth gradients. It’s ideal for small batches, full-color prints, and unique materials where other methods may fall short.

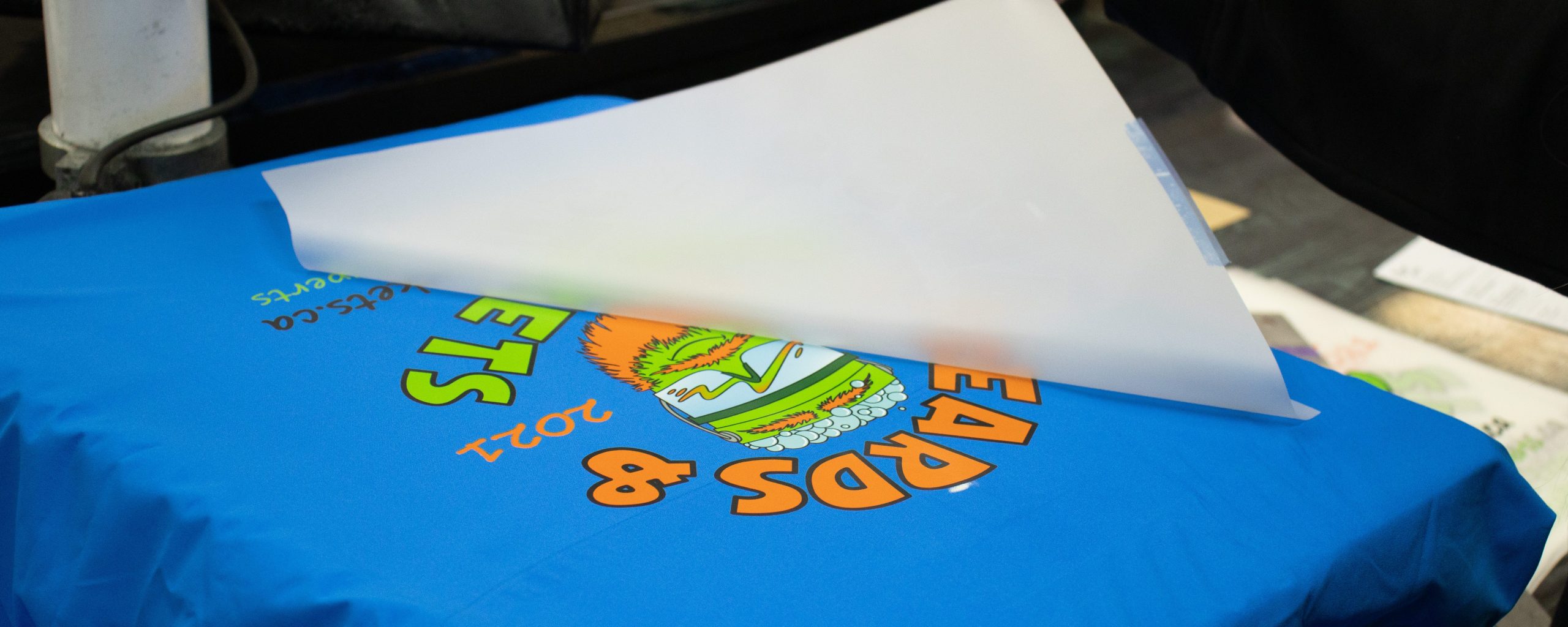

How DTF Works

DTF printing starts by printing your design in reverse onto a PET film using water-based or eco-solvent inks. A layer of adhesive powder is then applied and cured, creating a ready-to-press transfer.

Once cured, the transfer is placed onto the garment and heat pressed. This bonds the design to the fabric, resulting in a flexible, soft print that lasts through many washes.

Common Uses of Screen Printing

- Custom T-Shirts – Ideal for small-batch, full-color designs.

- Hoodies & Sweatshirts – Great for vibrant prints on thick materials.

- Activewear – Works well on polyester, spandex, and performance fabrics.

- Tote Bags & Backpacks – Perfect for promotional and retail items.

- Kidswear – Durable and safe prints for children’s clothing.

- Fashion Brands – Sharp detailing for limited-edition drops or streetwear.

- Team Apparel – Print names, numbers, or graphics on uniforms.

Whether you’re building brand recognition or outfitting a group, DTF delivers full-color design and high-impact results.

Pros of DTF

- Vibrant, Full-Color Prints: Great for complex or colorful artwork, including gradients and photo-like images.

- Works on Many Fabrics: Cotton, polyester, blends, spandex, and more.

- Low Minimums: Cost-effective for small orders and one-off designs.

- Durable & Washable: Stays bright and intact wash after wash.

Cons of DTF

- Feel of the Print: Slightly more noticeable texture compared to screen printing.

- Not Ideal for Bulk Orders: Setup is fast, but production time can be slower than traditional screen printing for large runs.

DTF vs. Screen Printing

DTF is best for full-color, detailed designs or smaller runs. Screen printing is ideal for bulk orders and solid-color graphics. Choosing the right method depends on your project needs and material.

When to Choose DTF

Choose DTF when you need small quantities, full-color prints, or want to print on hard-to-decorate fabrics like polyester or spandex. It’s also great for detailed artwork, fast turnaround projects, and when you want to test a new design without committing to large inventory.

Wash and Care Tips

To extend the life of your DTF garment:

- Turn them inside out before washing.

- Use cold water and a gentle cycle.

- Avoid bleach, fabric softeners or harsh detergents.

- Air dry or tumble dry on low.

- Never iron directly on the printed area—use a pressing cloth or iron from the inside.

Final Thoughts

DTF is one of the most flexible and vibrant printing solutions for modern apparel decoration. Its ability to print full-color designs on nearly any fabric makes it a go-to for custom wear, promotions, and personalized merchandise. If you’re looking for quality prints with no compromises, DTF delivers.